Sound port operations to protect the environment

By Jan Sierhuis* and Jesper Goodley Dannisoe**

The port is like a complicated organism with many processes and many of these may pose a threat to the environment, both the marine and the terrestrial environment. The daily routine works in a port is necessary and, in most cases, optimized to increase speed and reduce costs, but port managers are urged to take a look at how port operation and port design can support safe routines.

Port facilities are usually equipped with a drainage system to handle storm water. However, due to the multiplicity of goods handled in the port, spills may occur. Even if in small amounts and unless there are strict rules regarding immediate removal of any type of spill, they will eventually be washed to sea during the next rain event.

STORM WATER RUN-OFF

The impact from such an outlet of various materials may or may not impact the marine environment. However, depending on the orientation of the port and the design of the drainage system, this may lead to discharges, which are likely to spread along the coast. Proper management of a port will include precise instructions related to various types of spills, from dry bulk goods, like grain, to chemicals and oil. The daily use of sealed surfaces will prevent small amounts of rubber, oil, grease and other substances from immediately getting into the marine environment. However, even after six months of dry weather, this material will run off during the first shower. Proper installment of oil separators and sedimentation tanks for sand on the storm water system can substantially reduce the amount being discharged and thus help in reducing negative impacts from port operations.

In addressing storm water run-off, ports should also consider installation of reservoirs to catch rainwater for cleaning applications and other uses such as watering plants. This will reduce the amounts of industrial waste discharged into the environment but will also help significantly in conserving fresh clean water. Increasingly, many ports are looking at using infrastructure to cope with potential climate changes. One of the new inventions is permeable surface systems, which can store large volumes of water while keeping the surface relatively free of puddles.

PREVENT OIL SPILLS

It is best for a port to prevent oil spills from happening. The port must develop contingency plans which outline what to do when an oil spill occurs. Such plans must be able to deal with both spills on land which may end up in the water, as well as direct spills into the sea. There are multiple response techniques (mechanical collection and recovery, dispersing, in situ burning, natural attenuation) but, generally, oil spills may be very difficult to contain.

The spread of oil on the sea can be very fast, depending on the type of oil and on prevailing weather conditions. Well-organized contingency plans may include modeling results from a number of scenarios under different conditions. Trial-spills are informative when designing a plan for an emergency clean-up.

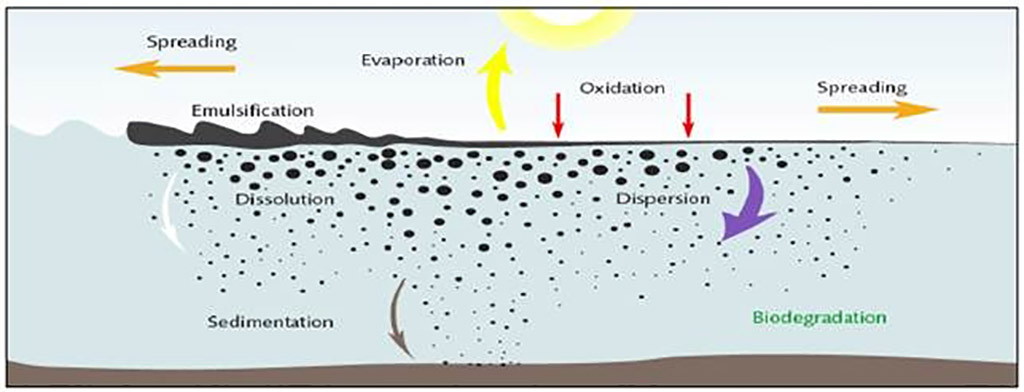

The various weathering processes that effect spilled oil are shown in Figure 1.

[Figure 1. Processes acting on spilled oil (from Fate of Marine Oil Spills (2002). Many of the processes are highly dependent on temperature, wave movements and the wind (strength and direction).]

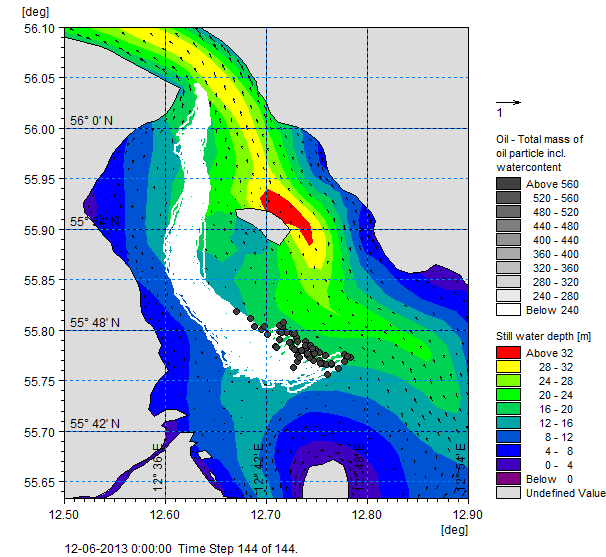

An oil spill at sea will spread mainly according to the wind direction but also with sea currents. As mentioned, an oil spill model can be used to determine the potential track and spreading. Figure 2 showing an oil spill from a ferry was simulated. The oil track was followed for 48 hours. The oil front moved approximately 30 km south.

[Figure 2. Simulation of a spill, followed for 48 hours.]

Port authorities should consider how an oil spill could propagate if it happens in the port from either a land-based source run-off (through a storm water drainage system) or from ships moored in the port. Such studies will enable the port manager to train staff and to ensure that suitable equipment is available for such disasters. Port authorities should take the potential damage on vulnerable ecosystems into account, e.g. coral reefs, seagrass beds, mangroves and adjacent beaches. Vulnerability of habitats at risk will be determined if proper baseline studies or habitat mapping around the port have been undertaken.

Oil spill cooperation in the Caribbean

Port operations will have an impact on the marine environment. The task at hand is how to minimize this impact; and, how to contribute to improving deteriorated areas. In this regard, port managers have an obligation to their businesses and communities. They also have an international obligation.

Under the Cartagena Convention and Oil Spills Protocol and particularly article 11, the Contracting Parties must “co-operate in taking all necessary measures to respond to pollution emergencies in the Convention area” and shall, “individually and jointly, develop and promote contingency plans for responding to incidents involving pollution or the threat thereof in the Convention area”. Under this regional instrument Caribbean countries have worked on the development of a regional OPRC Contingency Plan (Oil spill Preparedness, Response and Cooperation) under UNEP/IMO guidance. This plan provides a framework under which island-states and territories may cooperate at the operational level in responding to oil spill incidents, as required by Article 8 of the Protocol to the Cartagena Convention.

Regional oil spill cooperation: Caribbean OPRC coverage

Caribbean national economies depend on tourism and clean beaches. However, the Caribbean Sea is plied by heavy maritime traffic. Oil refining and distribution are also major industries. Some 13 million barrels per day, representing 17.9% of world production, were produced in the wider Caribbean region in 2012 (source: OPEC, 2013). Caribbean countries and particularly the smaller island-states are therefore vulnerable. Their individual response capacity is insufficient to effectively manage large oil spills. Regional cooperation is the most effective method to manage these risks and to protect both the abundant marine life and the vulnerable national economies.

On the international level, the efforts are monitored by UNEP and IMO, who design and fund regional programmes to keep the Cartagena Convention on national agendas and ensure that an effective regional cooperation system is in place. Regional Marine Pollution Emergency Information and Training Centre for the Wider Caribbean (RAC/REMPEITC-Caribe) is an activity centre, hosted by the Government of Curacao since 1995. It provides technical assistance to countries in the wider Caribbean region for the ratification and implementation of the OPRC Convention; their oil spill contingency planning; and it monitors the existence of national oil spill contingency plans that are approved, up-to-date and effectively implemented. Since the opening of the centre in 1995, the ratification of the OPRC Convention has increased from 12% to 59% of the total countries and territories of the wider Caribbean region. Currently, 36 Caribbean states and territories are part of a regional OPRC Plan.

The plans are designed as 3-tiered response procedures to enhance the ability of an island-state to respond effectively to a spill that is beyond its capability. Of the 36 OPRC territories, 19 currently have an approved national plan and 14 have a draft plan. That represents 92% coverage for the wider Caribbean region. The ratification of the OPRC Convention is important for mitigating oil spill risks. For more information, please contact your national maritime administration or visit the RAC/REMPEITC-Caribe website.

NATIONAL OIL SPILL CONTINGENCY PLANNING Ports play a key role in the design and effective implementation of national contingency plans and port managers should assume an active role in the planning. Port managers should ask: is our oil spill plan up to date? When was the last oil spill exercise? What is the plan and objectives in the coming year and who should be involved?

All initiatives in this regard should be part of a national contingency plan that involves all stakeholders. In many territories, port managers are assigned the role of national oil spill coordinator in port areas. The national oil spill plan should contain information about the designated national entities responsible for oil spill matters; the identified risks and sources of oil spills; the identified resources for combating spills; the available logistics support and oil storage/disposal facilities; communication capabilities and procedures; and an oil dispersant policy and plan for national territorial waters.

One of the international obligations under the OPRC Convention is regular updating and exercising of the national and port contingency plans. Periodic drills and reviews keep the plan up to date and personnel informed and involved. Responsible port managers will include drills and exercises in their annual budgets and will ensure other port stakeholders do the same. It is wise to assign the job of organizing drills and updating plans with port stakeholders to the harbour master or port operations manager. The RAC/REMPEITC-Caribe, if requested, will assist countries in the wider Caribbean region with this process.

Port managers can help to minimise oil spill risks by smart design and operations. Notwithstanding, spills will occur. And ports therefore need to be prepared to handle them. There are regional tools available to manage the risks, but it is imperative that a national oil spill contingency plan be designed, periodically reviewed, tested and updated. This requires know how, dedication and financing. Knowledge is available in the region. Dedication and financing are the responsibility of ports and governments. They must inform the public about capabilities and plans to cope with severe oil spills. This benefits the society and creates awareness and public goodwill in the event of actual spills and disastrous incidents. []

FIRST PUBLISHED; 2015 June 1

* Jan Sierhuis, Director, Maritime Authority of Curacao

* Jan Sierhuis, Director, Maritime Authority of Curacao

(maritimecuracao@gmail.com)